-

flexible

Capacity allocation

-

25 years

Professional casting experience

-

Independent optimization

Ability to improve equipment

-

Industry leading

Automatic production line

- 智能配料

- 造型设备

- 自动平口

- 自动套丝

- 成品检验

- 成品产出

- 智能仓储

Strict control of manufacturing environment

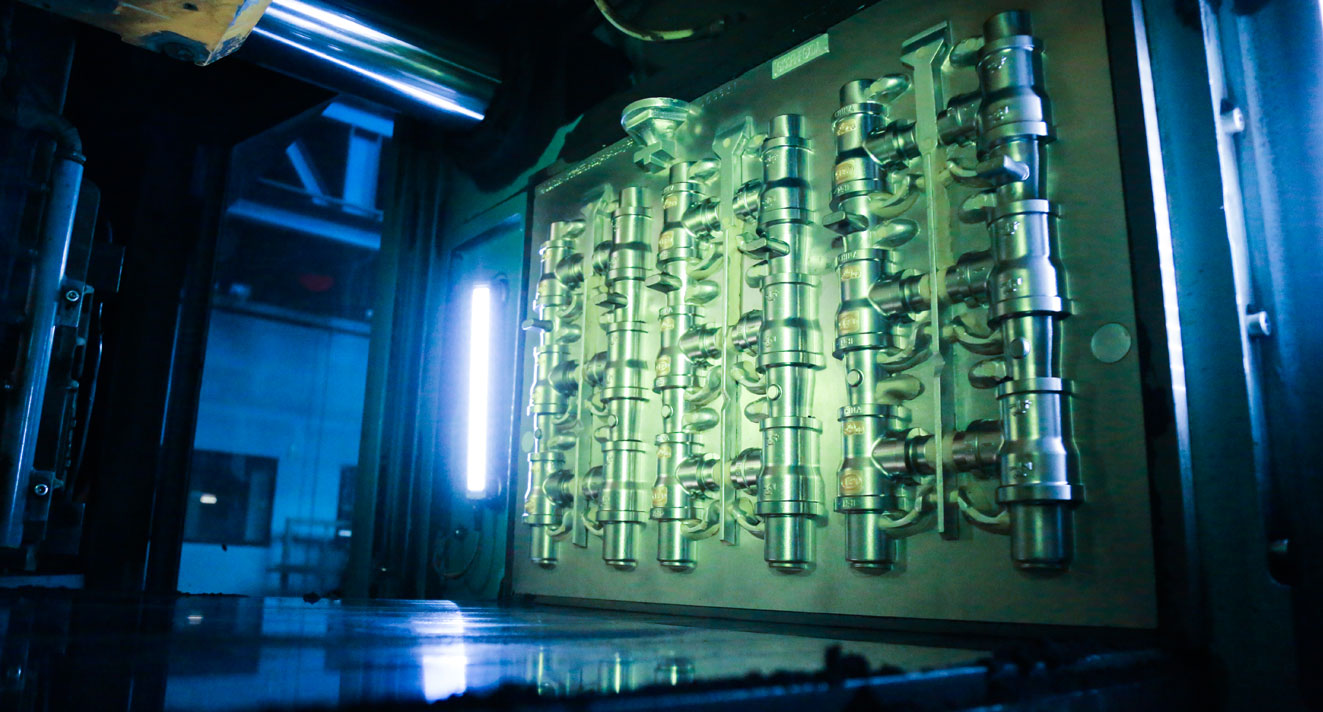

智能配料

Automatic vertical feeding and accurate measurement

准确控制烧结时间以及温度

保证优质砂芯质量

Strict control of manufacturing environment

造型设备

Using disa D-3

垂直造型设备

高效铸造优质产品

Strict control of manufacturing environment

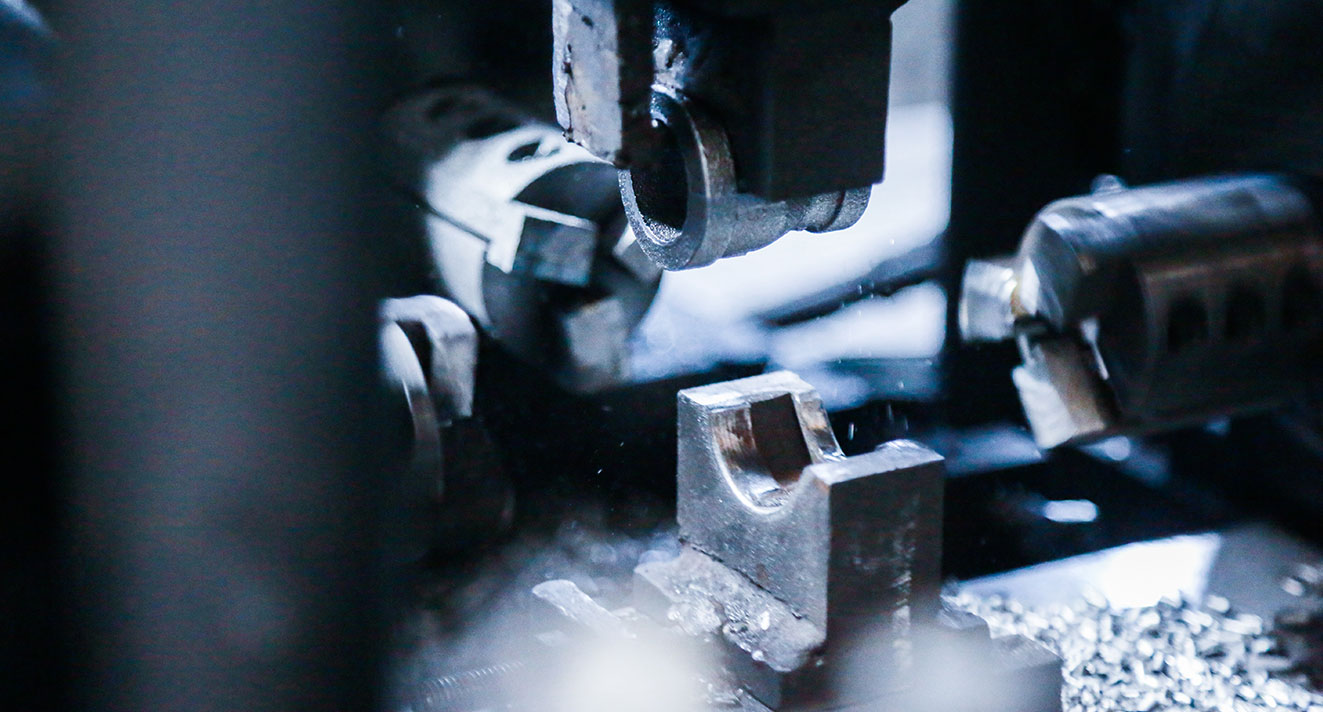

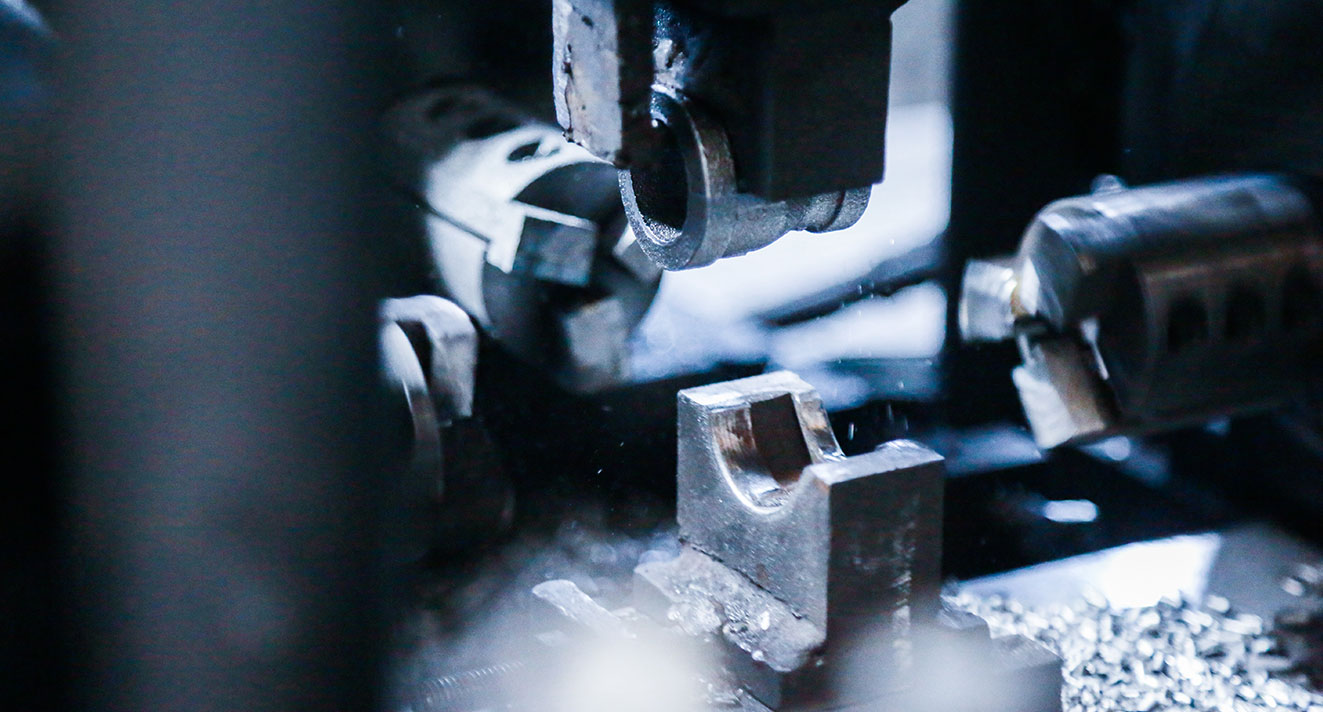

自动平口

Fully automatic electrical equipment to ensure production beat

剔除棱角只留完整产品

精确切割管件本体多余部分

Strict control of manufacturing environment

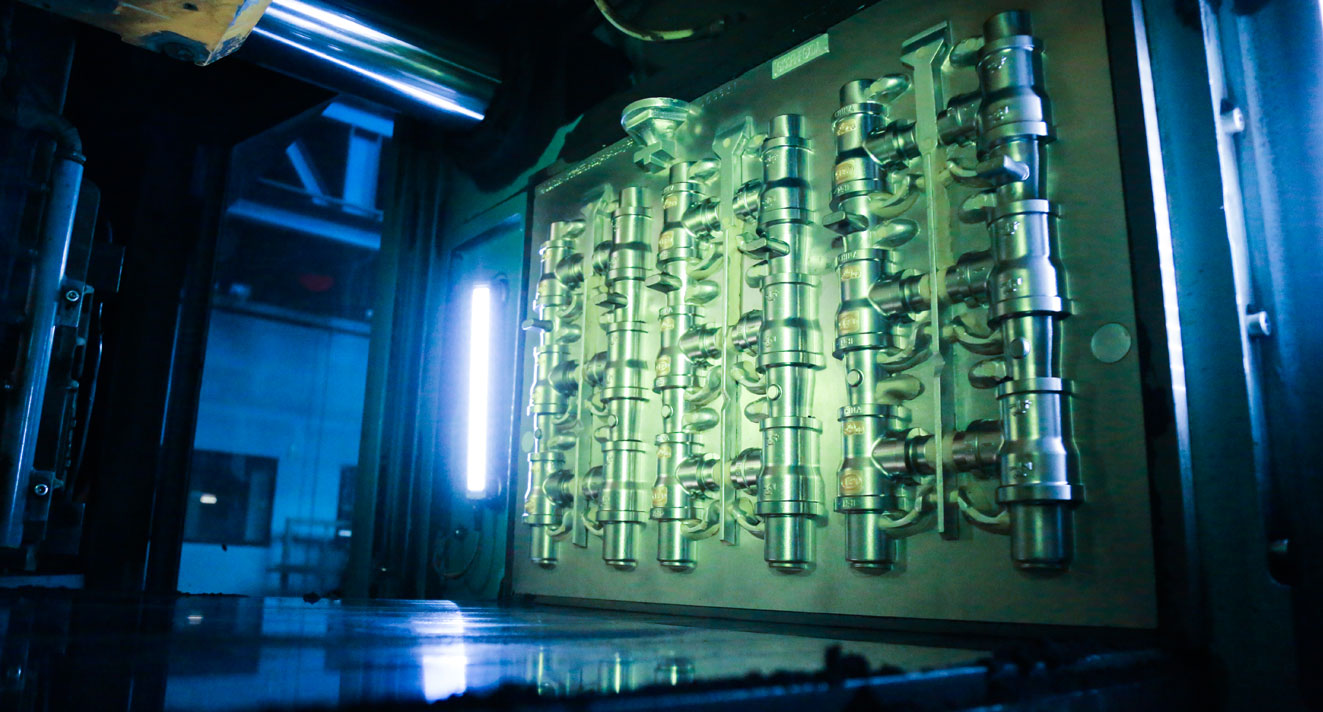

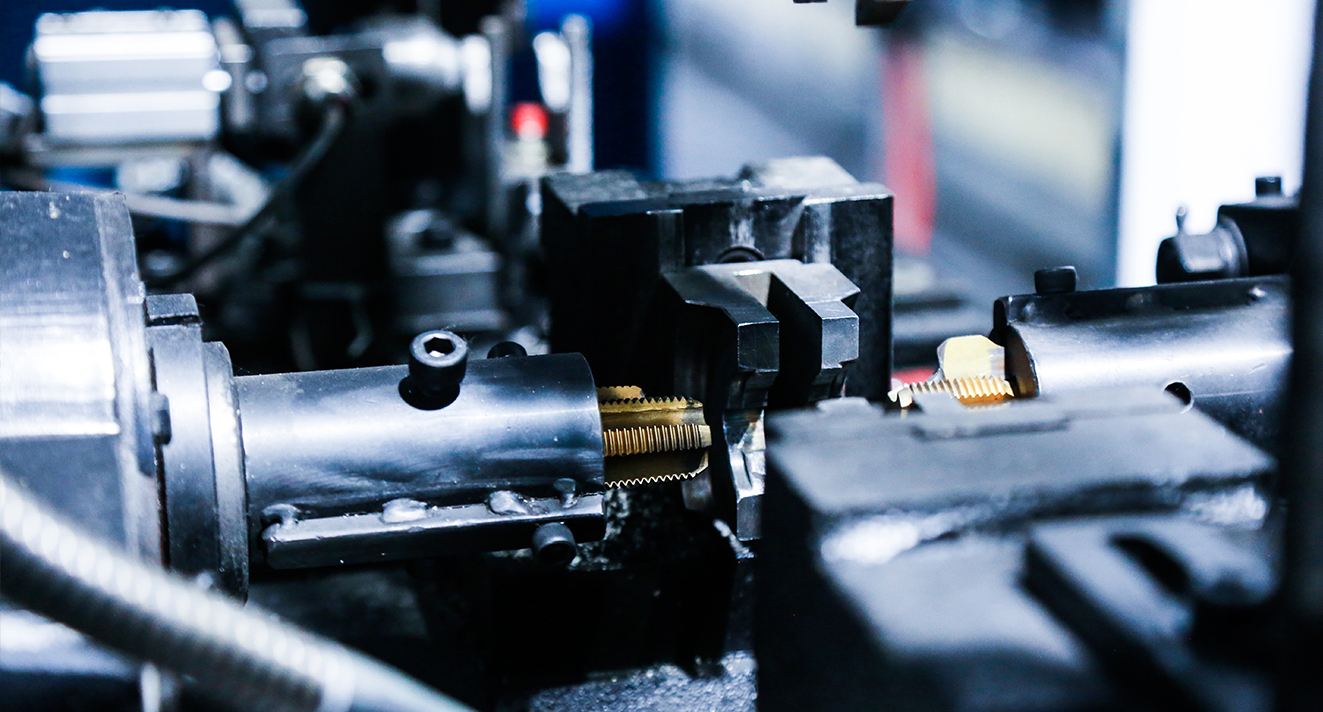

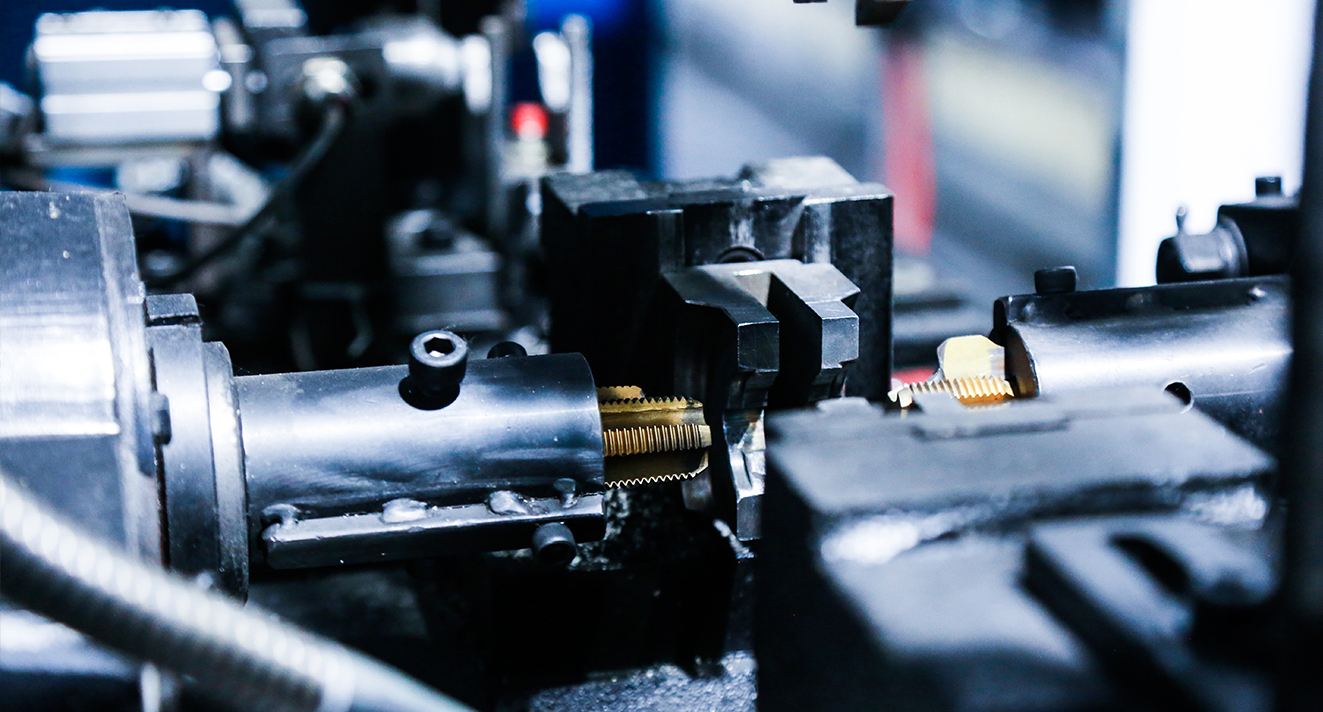

自动套丝

Full automatic threading equipment

智能设备

省时省力

Strict control of manufacturing environment

成品检验

Omnidirectional precision inspection

100%经过逐个检验

确保镀锌层完全覆盖

Strict control of manufacturing environment

成品产出

The details are controlled layer by layer

全自动清洗烘干设备

管件表面洁净靓丽

Strict control of manufacturing environment

智能仓储

Precise intelligent control

无缝提升大数据

无缝对接ERP