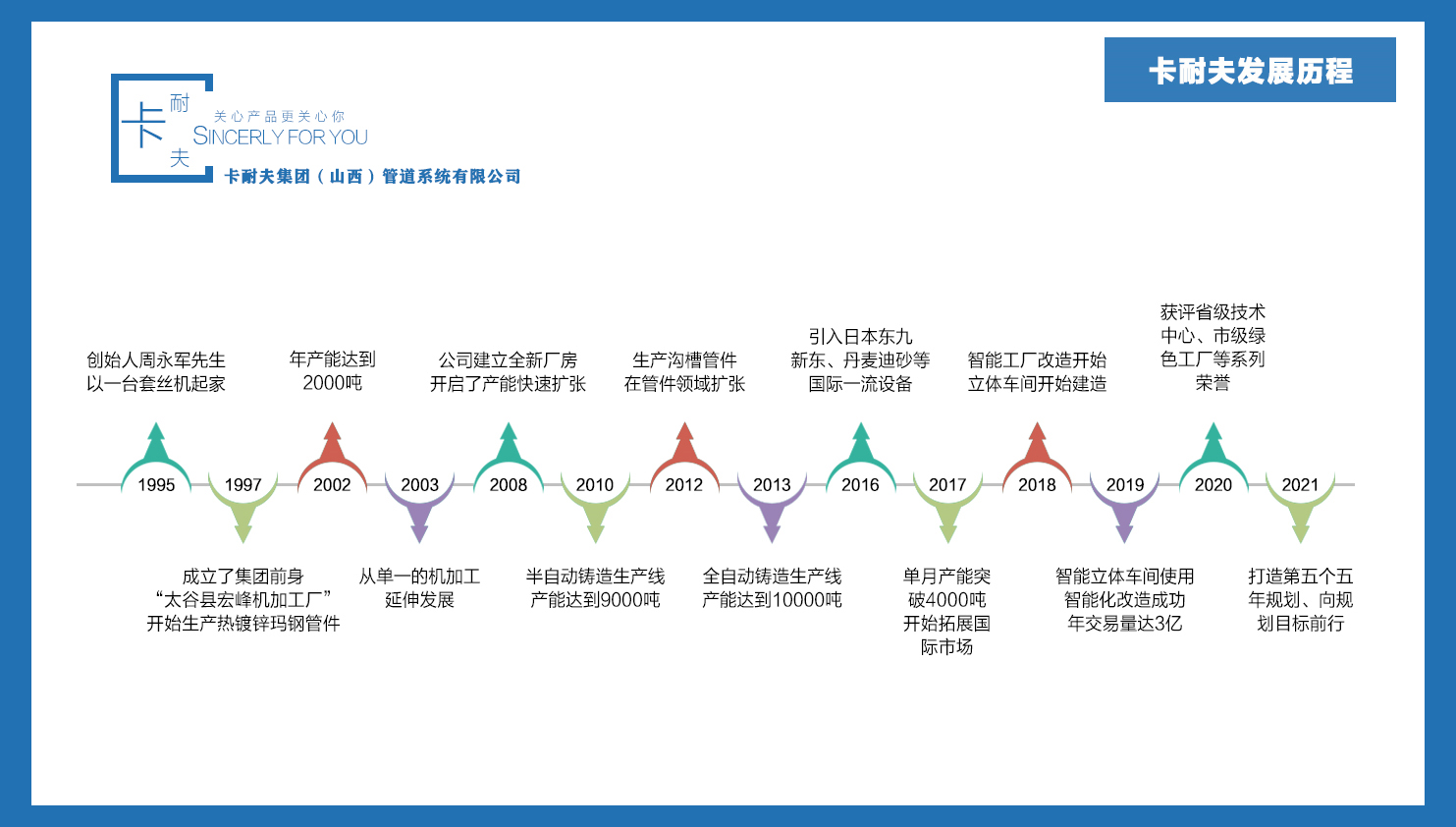

Karnev group (Shanxi) pipeline system Co., Ltd., founded in 1997, is an industrial foundry enterprise with the mission of producing and supplying high-quality and cost-effective pipeline system accessories. With an annual output of 50000 tons, the company has the production capacity of the whole process of mold, casting, heat treatment, hot galvanizing, processing and assembly. Provide products, services and solutions for water supply and drainage system, fire protection system, natural gas system, air conditioning and HVAC system, mechanical equipment and other systems. With a registered capital of 100 million yuan, the company has more than 1000 employees and a total asset of 350 million yuan. Its products are exported to home and abroad and are highly praised by the majority of users. Brand K & F stands for the English word "keep and firm", which means that we firmly abide by our commitment to the product "firm and long-term". In the course of operation, the enterprise has won various honors in the society and relevant units. The fifth director unit issued by China Hardware Association has won the top ten enterprises in environmental protection management, model unit of Taigu County, chairman unit of Taigu County Federation of industry and commerce, advanced unit of scientific and technological innovation, demonstration unit of Lixin, well-known brand of China Maanshan Iron and steel pipe fittings, advanced unit of environmental protection transformation "Four new" enterprises, "special, fine and new" excellent foundry enterprises, provincial enterprise technology center, won the high-tech enterprise certificate in 18 years, municipal green factory, class B enterprise and other honors in 20 years, and provincial enterprise technology R & D center.

The company has 5 full-automatic molding lines, including 2 Yonghong lines, 2 Desa lines imported from Denmark and 1 Dongjiu molding line from Japan. It is equipped with 10 electric furnaces in Shanghai Xinyan and Rizhi, and 1 set of natural gas annealing kiln. All dust producing points in the production process are equipped with dust accumulation covers and corresponding dust removal equipment. According to the government regulations, the cupola is equipped with cuiyungu ultra-low extraction soot meter. There are 26 dust removal equipment. The dust collector is a side inserted flat bag back blowing cloth bag for dust removal. It is designed in Europe, the key parts are imported, and the system quality is reliable. Compared with the traditional round bag dust collector, which can only meet the performance at the initial stage or basically meet the domestic emission standards, the equipment maintains excellent operation performance and smoke emission index ≤ 10mg / Nm3 (until the filter bag needs to be replaced). The dust collector motor is Honeywell motor imported from the United States, which can effectively save energy, reduce consumption and reduce noise. There are 3 sets of sewage treatment systems, The company's industrial and domestic wastewater reaches the reclaimed water quality standard after treatment, which is used for internal watering and dust suppression. Motor vehicles shall be gradually replaced with electric vehicles, access control shall be strictly implemented, and vehicles below the national five-year plan shall be prohibited from entering. The company is one of the first enterprises in Taigu to install the power online monitoring platform, improve the sub meter recording system, and effectively count the power consumption of production and environmental protection equipment. In response to the national environmental regulations, vigorously promote advanced, energy-saving and efficient technical equipment and processes, improve energy-saving organization and management, and strive to build a resource-saving and environment-friendly enterprise.

The company continues to make technological innovation, promote the renewal of production equipment, product standard innovation, industrial informatization and intelligent development, and in line with the business philosophy of "quality first and reputation first", pay close attention to management, strictly control quality, forge ahead, continuously improve product quality and technical content, and establish a provincial enterprise technology R & D center. At present, it has obtained 22 utility model patents, 1 invention patent. In the production process, the company followed the development needs of advanced technology in the international market and introduced mold flow technology.

From 2017 to 2021, the heavy equipment of "Carnegie intelligent manufacturing platform" costing hundreds of millions of yuan set sail. At the software level: Kingdee ERP system, Dongjie WMS system, yunzhijia mobile OA system, Huazhong casting management system and customized MES system cooperate in parallel, so that the management can accurately grasp the data of personnel, equipment, materials, production, assets and so on; Hardware level: intelligent three-dimensional warehouse, high-efficiency flow line, fully automatic flat mouth shaping and threading equipment, galvanizing equipment, pouring equipment, high-standard power detection platform, etc. help every link in production and bring the traditional "manufacturing" to the new "intelligent manufacturing". Externally, discuss and learn from each other with intelligent professional enterprises; Internally, strengthen the training of employees, so that each employee of the company has a clear understanding of intelligent manufacturing, gradually deepens it, and leaves no room for the comprehensive development of its functions, so as to guide and promote the comprehensive transformation of the local casting industry to intelligence. The company also continues to focus on building a resource-saving and environment-friendly enterprise, and always adheres to the policy of environment and occupational health and safety: energy conservation, environmental protection, health and safety. Observe the rules and discipline, and put prevention first. Full participation and continuous improvement; Give back to the society, achieve win-win results for local enterprises, continue to promote enterprise development, create more employment opportunities for the society, and increase support for social public welfare undertakings.

We promise: because of our profession, we are excellent; Because of excellence, we are trustworthy; Because of trust, we will do better!